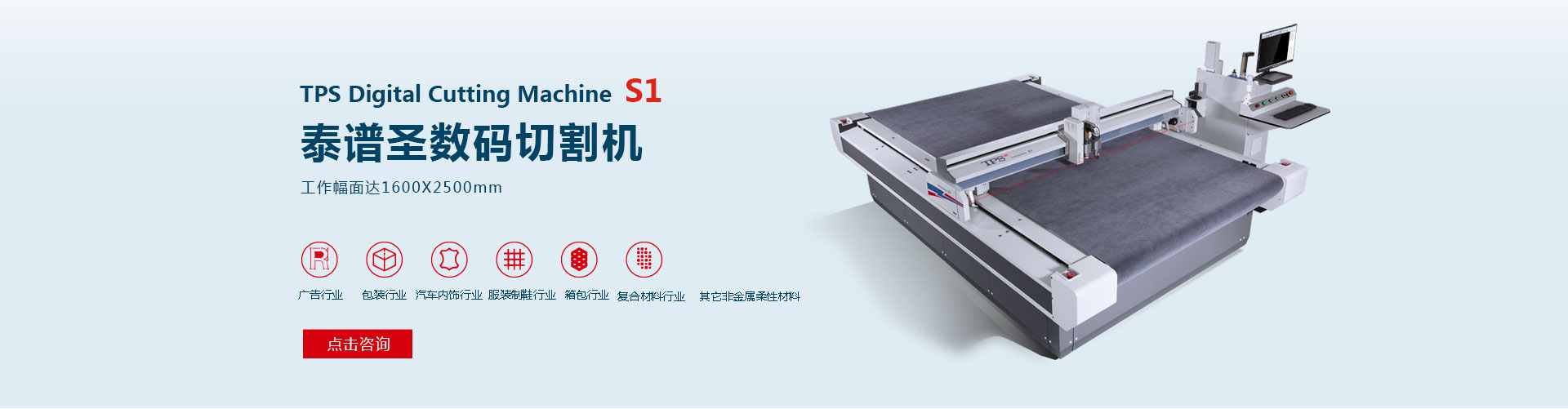

Cutting Machine Overview

TPS cutting machine mainly focuses on the intelligent cutting of non-metallic material in different graphics, it can quickly complete various processes such as full-cutting, half-cutting, boring and milling, punching, creasing, marking, etc, solving the problem of cutting special-shaped graphics and improving production efficiency, which suits sample-making and small batch production. It also solves recruitment difficulty, lowers labor cost and reduces defective rate resulting from manual cutting deviation.While lowering costs, it cuts with high quality, high stability and high accuracy, helping users improve competitiveness and grasp more market shares.

Features of cutting machine:

1.TPS independently researched and developed CAM software can prevent over-cutting at inner angles, thus recover graphic outline maximally.

2.Intelligent tabletop mapping function: The flatness of tabletop is measured by tabletop mapping with the high-precision height detector automatically, and the tabletop can be height-compensated in real time by the TPS software to ensure perfect cutting effect.

3.Realizing matching the cut shapes of front and back sides intelligently according to the material edge.

4.Automatic tool calibration: Tool exchange is quick and effortless thanks to the fiber laser tool tip height sensor. It accurately and automatically calibrates the working depth for different tools and greatly contributes to simple operation.

5.Quick-replacement universal modules get operation easy and efficienct.

6.Multi-task repeat cutting, intelligent absorption.

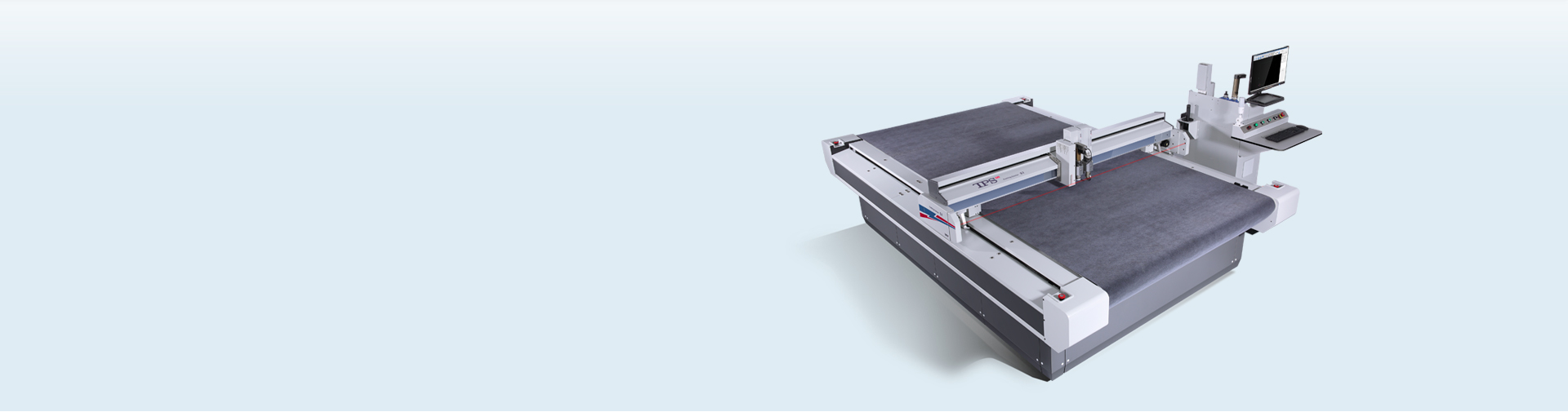

Diverse tools

TPS digital cutting machine is equipped with advanced, standard and universal tool modules for replacing tools easily and quickly. It is very handy during processing a wide variety of materials.

-

Universal module

-

universal tool module and tool unit

-

High performance high speed milling router

-

Multi-angle V-cut tool

-

Creasing tool

-

Wheel knife tool

-

Electric oscillating knife

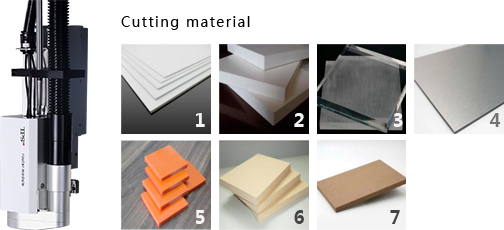

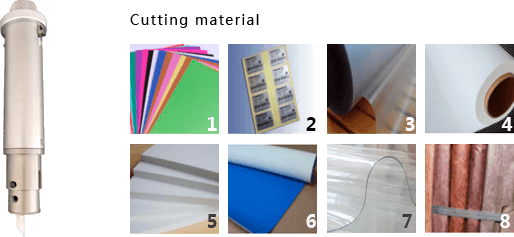

Different material, Different tool, Multiple options

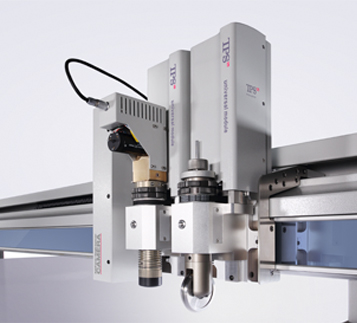

1

High performance high speed milling router

According to different materials and application, the imported high speed and high performance spindle motor can reach its highest speed 60000rpm and can cut non-metallic hard material as well as flexible material of 20mm thickness with more smooth cutting edge. It has distinguished performance from traditional cutting equipment and can work 24hours/7days incessantly, realizing the maximum output. The equipped professional and efficient vacuum cleaner absorbs smell and dust in cutting, which is good for workers’ health and meets environmental protection standards.

2.PVC foam board

3.Acrylic

4.Aluminum-plastic plate

5.Insulating board

6.MDF(medium density fiberboard)

7.Density board

2

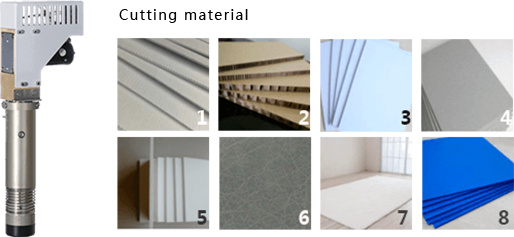

Electric oscillating knife

Electric oscillating knife cuts through material according to the theory of ultra-frequency oscillation. It is equipped with multiple amplitude knifes for different materials, which ensures high speed, efficiency and quality. The blade is also adjustable like 45°,26°,14°for different material thickness.

2.Honeycomb board

3.KT board

4.Grey board

5.PVC foam board

6.Leather

7.Carpet

8.Corrugated plastic board

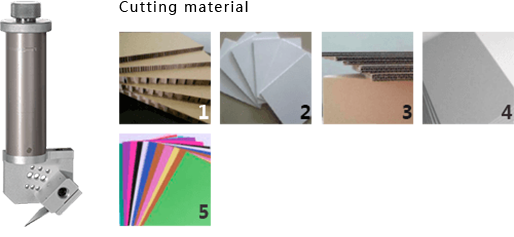

3

Multi-angle V-cut tool

The groove line can be adjusted according to specific cutting needs. Available angles are 0°,15°,22.5°,35°,45°. Maximum thickness is 16mm.

2.Medium hard PVC foam boar

3.Corrugated board

4.Grey board

5.Cardboard

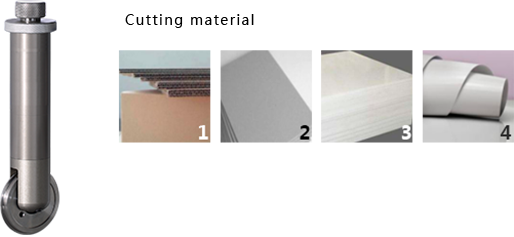

4

Creasing tool

Creasing tool creases material with creasing wheel and achieves perfect creasing effect by changing wheels with suitable depth and width. By adjusting oriented pressure, together with software creasing tool, it can crease forward and backward with higher quality and without breaking top layer paper.

2.grey board

3.PPC

4.Art paper

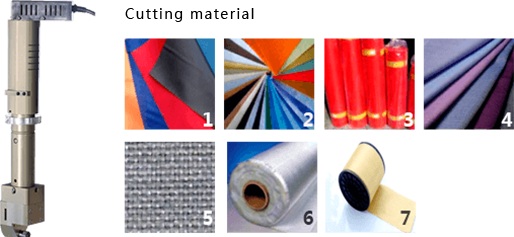

5

Wheel-cut tool

Wheel-cut tool is driven by high power brushless DC motor to cut material with high speed rotating blade. It can be equipped with round blade or decagonal blade.

2.Non-woven fabric

3.Banner fabric

4.Textile fabric

5.Knit material

6.Fiberglass

7.Aramid fiber

8.Carbon fiber

9.Carbon fiber composite

6

Drag tool

Suitable for soft material≤5mm

2.Sticker

3.Thin plastic

4.PP backside glue

5.PVC foam board

6.Rubber blanket

7.Soft glass

8.Artificial leather

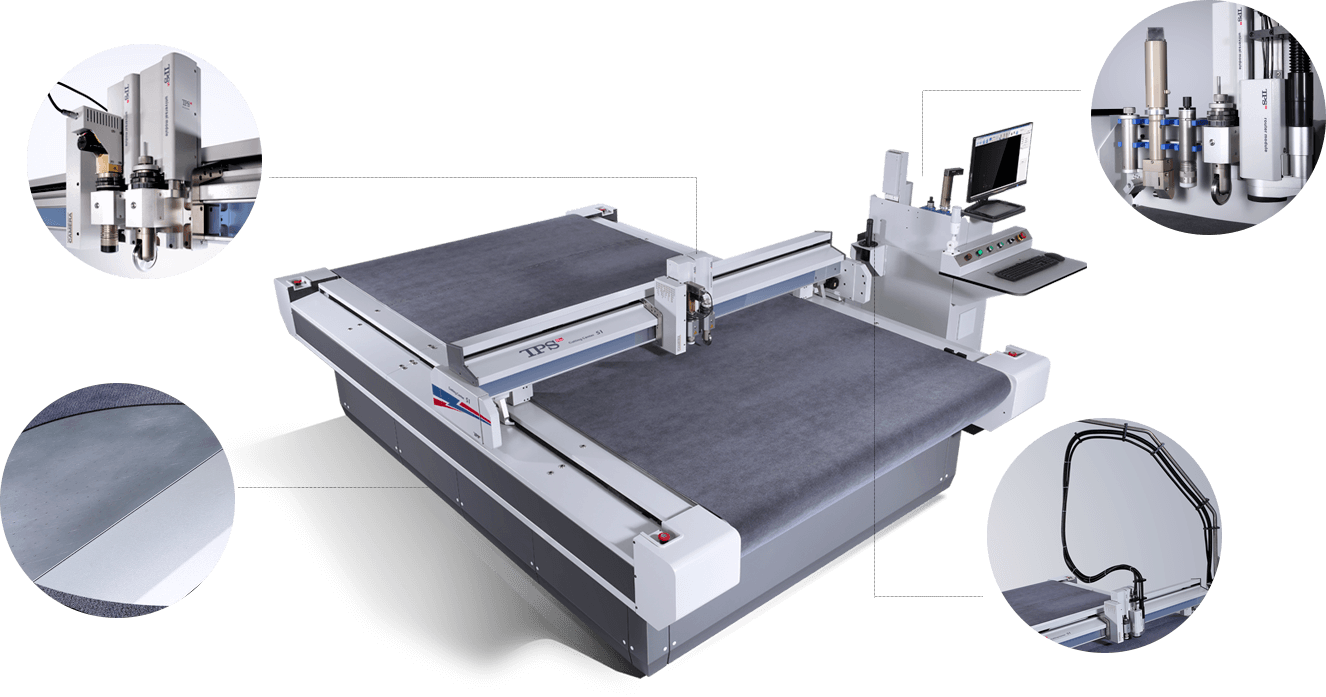

Advantages of cutting machine’s Hardware

Quick replacement tool modules

TPS digital cutting machine is equipped with advanced and universal tool modules, which makes tool replacement easily and quickly. It is very handy during processing a wide variety of materials.

A wide variety of tools

Full range of tools: milling router, oscillating knife, V-cut tool, drag tool, creasing tool, kiss-cut tool, plotting pen, etc.

Different tools are applied for different materials.

Vac-Sorb Almag alloy platform

The platform is durable and non-deforming with vacuum absorption design: strong wind and strong suction(easy for absorbing small items).

Vacuum cleaning pipe and base stand

The whole cutting process is without smell and dust, which is good for workers’ health and meets environmental protection standards.

European design style

Under the idea of European industrial equipment design, the machine is top-end, stylish and technological on the premise of ensuring machine performance.

Integratedly welded base stand

The welded frame is more stable, more rigid and anti-deformation .

Quick tool replacement module

Universal module can be combined with tools freely, realizing quick replacement of tools.

Full range of tools

Router, oscillating knife, V-cut tool, drag tool, creasing tool, kiss-cut tool, wheel-cut tool, plotting pen,(different tool for different material)

Honeycomb aluminum tabletop

It is durable and undeformable with vacuum absorption that has strong wind and strong suction.(easy for sucking small items)

Tabletop belt

Imported material, durable, has good air permeability and a long service life, which reduces using costs to minimum.

Sealed dust-proof design

Sealed dust-proof design reduces the failure rate of machine and extends its life.

Emergency stop buttons at 4 corners

If there is an error operation, press the button to stop the machine to reduce loss.

Interference immunity

Considering of the complex electromagnetic environment during operation, machine is especially equipped with anti-interference operating screen in case of blurred screen.

Safe operating environment

Infrared automatic induction safety device will maximally ensure operators’ safety while working and at the same time avoid material waste.

Rolling material feeder

The guide roller feeding device ensures that the feeding process in cutting is smooth and fluent. It can be set according to roll material’s specifications and features to enhance both output and cutting quality.

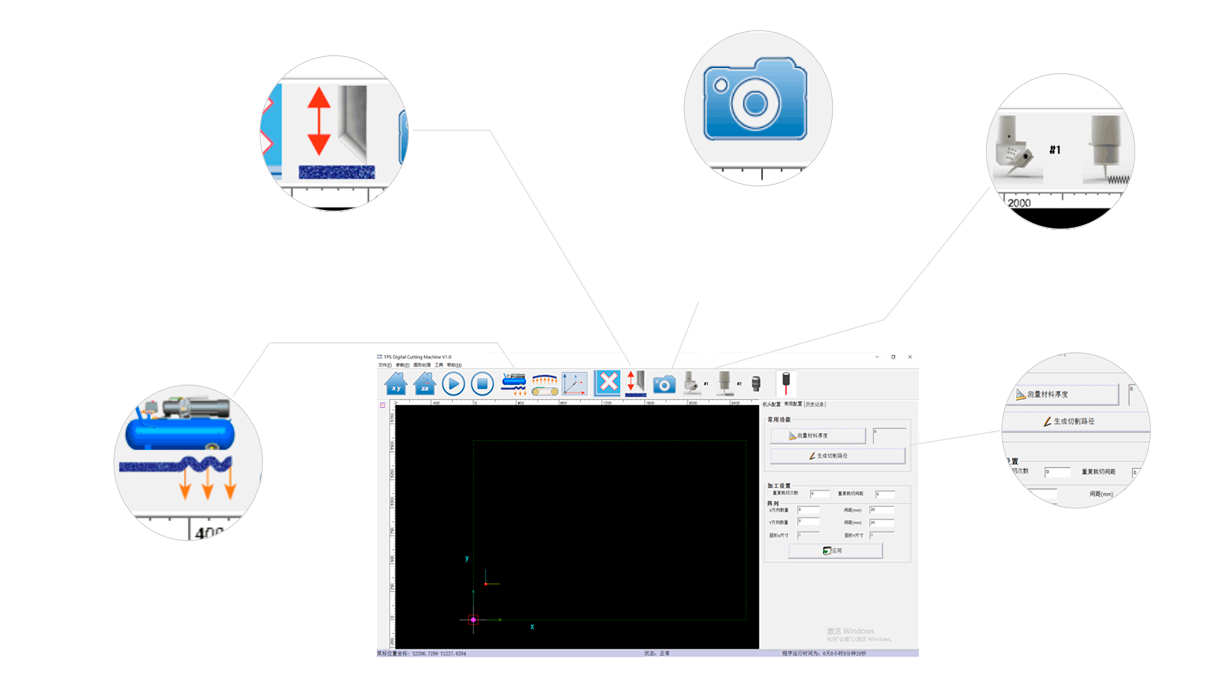

Software features

TPS digital cutting machine adopts self-researched and self-developed CAM software, whose design perfectly combines with user’s needs. It is a full-automatic intelligent cutting system that integrates performance,speed and quality, which can realize various craftworks like full cutting, half cutting, boring and milling,punching, creasing, marking etc. Easy operation, multiple and practical functions, together with tool modules quick replacement can meet customized needs of users.

Automatic tool calibration

Tool or bit exchange is fast and effortless thanks to the fiber laser tool tip height sensor. It accurately and automatically calibrates the working depth for different tools and greatly contributes to simple operation.

High definition CCD camera

The high definition CCD camera can realize automatic positioning and cutting on various materials, which eradicates problems like inaccurate manual positioning and print deformation.

Automatic switch of two heads

Two heads can switch automatically during cutting process, which satisfies different technological requirements of different materials.

Vacuum absorption

Strong wind and strong suction with optional size of vacuum absorption area, which greatly reduces electricity consumption.

Material automatic recognition

Material thickness can be automatically measured instead of manual measurement, then it will be recorded into the software.

Operating interface

The high-accuracy height detector will detect tabletop evenness and real-timely correct it through software to realize accurate cutting.

Control system

Adopting high performance multi-axis motion control system, which is convenient and economical to maintain and provides personalized development service.

Working pattern

Adopt control mode of “servo motor drives screw” and it can connect with computer to preset and store knife depth and knife pressure.

Graphic design software integration

It is compatible with software like ArtiOSCAD, AutoCAD, Coreldraw, simplifying workflow for structure and graphic designers.

Over-cutting prevention

The TPS independent researched and developed CAM software will prevent over-cutting at inner angle, maximally reverting graphic outline and achieving perfect cutting effect.

Automatic tool calibration

Tool or bit exchange is fast and effortless thanks to the fiber laser tool tip height sensor. It accurately and automatically calibrates the working depth for different tools and greatly contributes to simple operation.

Graphic positioning

High definition CCD camera and edge automatic recognition can realize automatic positioning on various materials and match the front side with back side, eradicating inaccurate manual positioning, print deformation etc. Together with automatic transmitting function, it allows efficient and accurate cutting on large format graphic, enhancing both output and cutting quality.

Matching cutting of front and back sides

Combining with edge recognition function, the software will swiftly recognize material edges and position, realizing the matching cutting of front and back sides intelligently.

Data interface

The internet interface allows updating and maintenance remotely with fast transmitting speed and over long distance. It can transmit with multiple computers simultaneously.

Material thickness automatic recognition

Material thickness will be automatically detected without manual measurement, then it will be recorded into the software.

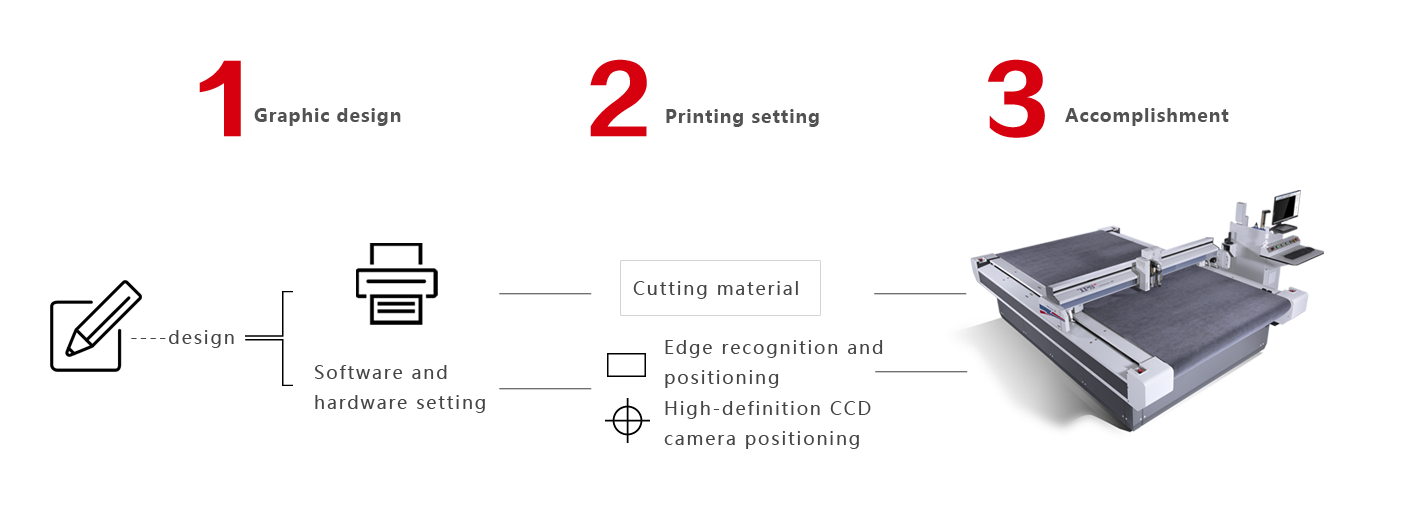

Cutting workflow diagram

Technical parameters

Main technical parameters of the machine

| Item: | Parameter: |

|---|---|

| Equipment power: | 2.5kw |

| Vacuum pump power: | 7.5kw |

| Voltage: | 380V 3 phase |

| Work area: | 1600x2500mm |

| Max. material size: | 1700x3000mm |

| Material max. processing height: | 50mm |

| Beam height: | 60mm |

| Max. processing speed: | 72m/min. |

| Servo motor qty: | 6pcs |

| Fixing method: | Welded integration |

| Cutting accuracy: | ±0.1mm |

| Positioning method: | High-definition CCD camera、Automatic edge recognition |

| Automatic media-feeding: | Yes |

| Applied material: | KT board, PVC foam board, PP, sticker, acrylic, corrugated board, honeycomb board, corrugated plastic, grey board, paper, leather, blanket, MDF, aluminum composite sheet, insulating board, fiber cloth, medium fiber board, flag fabric, textile fabric,etc. |

![{@me['title']}](/en/templets/default/images/i_banner1-2.png)